Thermal Instrument Model # 62-9 is a versatile flow measurement solution for both liquid and gas flows in larger pipe sizes, ventilation ducts, and stacks. The insertion probe style is adaptable to various line sizes and offers a variety of process connections.

The Thermal Mass Probe Flow meter is inserted directly into the flow stream to measure the flow rate of gases, liquids, or slurries in stacks, irregularly shaped lines, and process ducts. Unlike other probe flow meters, we offer a model that has no apertures that can be clogged with particles or distorted by wear

Features

- Versatile solution for liquid or gas measurement

- Repeatable rates within +- .2%

- Multi-point flow measurement available

- 100:1 turndown range (1000:1 Application dependent)

Our sensors are enclosed in a sealed tube which can be inserted or removed through a gate valve or a packing gland while conduit is in use. We also offer a mechanical retractor if required for your application. Our probes are manufactured using 316 SS as a standard, but corrosion resistant materials such as Hastelloy C, Monel, Inconel, Tantalum, and Carpenter 20 are also available. In addition, our Thermal Mass Flow Meters are available in a variety of protective coatings including Carbide, Fluorocarbon, Teflon, and Sulfinert.

Why are our flow meters so reliable and accurate?

Our Thermal Mass Flow Meters operate using a constant temperature system that employs two RTD sensors; one for sensing temperature, and one for sensing flow. The sensor is heated to a precise temperature above that of the fluid passing by. The Fluid conducts heat off the sensor in direct proportion to the mass flow rate. The temperature is used to set the heat on the flow sensor and correct for changes in the fluid temperature.

Enhanced Capabilities available with our Dual-Tip Probe

(Model 62-9DT):

We have increased our capabilities of our Model 62 insertion probe. This unit can now be installed in line sizes as small as 1 1/2″ in diameter. Some of the features are:

- High Gas Flow Rates

- High Temperature Range

- High Pressure Capabilities

- Smaller line size capability (See Specification Chart Below)

- 1000:1 Turndown Range Available

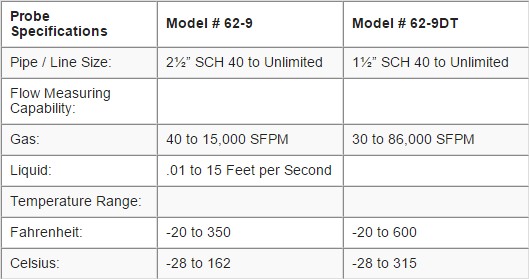

Insertion Flow Probe Meter Specification Chart