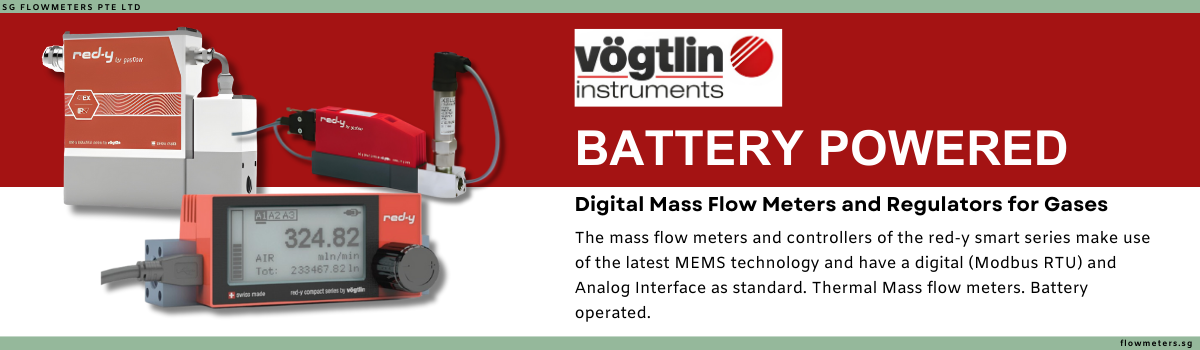

D-flux Multi Series

The d·flux multi series is a fast and reliable multi-parameter mass flow device for gases with measurement outputs for mass, normalized and volumetric flow, pressure and temperature.

The instrument is based on differential pressure measurement over an internal advanced laminar flow element. One of the many advantages of this laminar flow device is the ability to easily switch to a different gas without a loss in accuracy.

- Suitable for most common gases.

- Flow up to 1400 In/min (Air).

- Pressure up to 14 bar.

- Options: All stainless-steel, high accuracy, gold plated sensor for hydrogen.

- Vögtlin Connect App: can works with Bluetooth®

Features

Flow rates up to 1400 In/min

- The unit is available in 4 ranges (0-500, 0-700, 0-1000 and 0-1400 ln/min for air). Each range can be reduced by the user by 30% without any loss in accuracy (rate for air, other gases according to conversion)

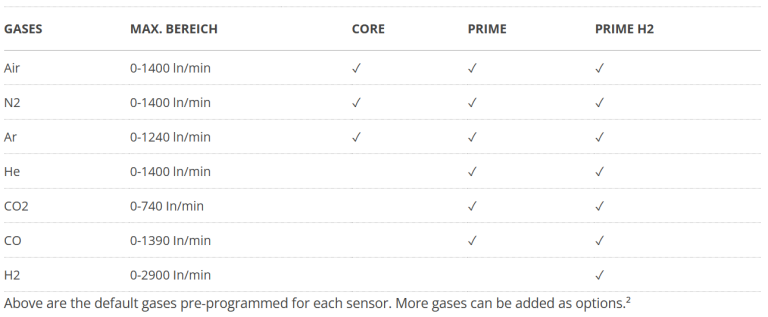

Multiple pre-programmed gases

- The d⋅flux multi series mass flow instruments can contain up to 15 programmed gases. More gases can be added at any time.

Communication

- The devices offer advanced Modbus communication & analog output.

- Optional Profinet or EtherCAT interface available (Ethernet IP available soon)

Wireless device access with the free Vögtlin Connect app

- The Vögtlin Connect app can be used with any Android phones and lets you easily and securely (password protected) connect to your d·flux device. Vögtlin Connect is a user-friendly configuration software and offers the adjustment of many device parameters.

Applications

- Bio/pharma Industry

- Gas Consumption Measurements

- Burner Control

- Gas Mix Systems

- Testing Systems

- Light semi-Industry

- Food Industry

- Energy Market

Specifications

Measuring ranges:

- LFE1400 from 0-1000 ln/min to 0-1400 ln/min

- LFE1000 from 0-700 ln/min to 0-1000 ln/min

- LFE700 from 0-500 ln/min to 0-700 ln/min

- LFE500 from 0-350 ln/min to 0-500 ln/min

Sensor option:

- Core: Suited for air, nitrogen, oxygen and argon. Mixed wetted materials.

- Prime: All stainless-steel 316L sensor suitable for all gases. High accuracy optional.

- Prime H2: Gold coating for Hydrogen. High accuracy optional.

Accuracy

- Accuracy is ± 0.5% of customer full scale and ± 1% of measured value. Sample rate of 1 ms, updated data every 10 msec and a total response time of 90 msec (controller 2s)

Repeatability:

- ± 0.2% of factory full scale (according to SEMI standard E56-0309)

Power Supply:

- Meter: 15-36 Vdc, (200 mA@24Vdc, regulated) / Controller: 24 Vdc ±10%, (2000mA@24Vdc, regulated)

Power in through M8-4P connection or optionally through D-sub connection (ripple should not exceed 100 mV peak-to-peak) We recommend that the body of this unit is properly connected to ground.

Pressure:

Operation pressure:

- 1 to 14 bar a.

Accuracy absolute pressure:

- <0.5% of measured value (not certified).

Pressure sensitivity:

- Prime and Prime H2 sensor: <0.05% factory full scale per bar (typical air).

- Core sensor: <0.08% of factory full scale + 0.1% of measured value per bar (typical air).

Temperature:

Environment/Gas:

- -20 to +60 °C (-4 to 140 °F)

Accuracy temperature:

- Typically, ± 0.5 °C (not certified)

Temperature sensitivity:

- <0.02% FFS* per 1 °C of inlet gas temperature @ 7 bar a pressure.

*Factory Full Scale (maximum flow range of the device)