The Thermal Mass Probe Flow meter is inserted directly into the flow stream to measure the flow rate of gases, liquids, or slurries in stacks, irregularly shaped lines, and process ducts. Unlike other probe flow meters, we offer a model that has no apertures that can be clogged with particles or distorted by wear.

FLOW SWITCH - (FS16)

Increased features, performance, and versatility are available in the FS16 Flow Switch. The FS16 provides visibility to the flow rate while providing alarm set Thermal Instrument Model # 600-9/FS16 Dual Alarm Flow Switch. Pictured with 1/2″ MNPT Pipe Connection for Water Flow. Flow Indicator @ 40% of Full Scale Flow Rate. points to help monitor your critical processes. Additionally, the FS16 can be configured to deliver fluid temperature across a 4-20 mA output. As usual, any instrument ordered from Thermal Instrument Company is designed to perform in industrial applications.

We build all of our flow elements out of 316SS, but offer other exotic materials as necessary dependent upon application need. Hastelloy, Tantalum, Monel, and others have been used in the harshest of flow applications. Our circuitry is housed in a cast aluminum enclosure that allows the end user to modify set points as necessary, quickly and easily. The instrument can be set up to monitor liquid or gas applications in line sizes as small as 1/4″ OD to large duct or pipe lines. If your process requires Flow / No Flow or the ability to set up a Low Flow Rate Alarm or High Flow Rate Alarm, or both, you have found the right switch.

Pictured at Right: Thermal Instrument Model # 600-9/FS16 with 1/2″ Pipe MNPT Process Connection. Low Flow & High Flow Alarm Set Points for Water. Flow Rate Indicator at 40% of Full Scale Flow Rate.

Key Features of Model FS16

- 10 Bar LED Flow Rate Indication

- (2) SPDT 10 Amp Relay Alarms Standard or (1) 10 Amp DPDT Relay Alarm (optional)

- 4 – 20 mA Temperature Output Available

- Adjustable Set Points & Hysteresis

- Available as both an in-line (Model # 600-9) or Insertion Probe (Model # 62-9)

The durability, accuracy, versatility, and ease of use of this mass flow switch make it the economical choice for your process flow application. The electronics are built into a cast aluminum condulet which can be mounted as an integral part on the Model 62-9 and 600-9. Allowing a plant technician to accurately field set the trip point by adjusting the potentiometer. Using a voltmeter, the technician can then compare trip point voltage with the calibration voltages given on calibration chart provided with each meter. Trip high/trip low function can be field enabled with a simple jumper change.

- (1) Form C (SPDT) 5 Amp Relay

- Field Adjustable Alarm Set Point

- Field Adjustable for Trip High / Trip Low

- Integral or Remote Mounted Circuitry

- All Welded 316SS Body Standard

- Special Materials Available for Corrosion or Abrasion Resistance

- In-line or Insertion Probe Option

- Unobstructed Flow Path with Negligible Pressure Drop on Model # 600-9

- Numerous Process Connections

- 250 to 500F Service

- Pressure & Temperature Compensated

- Protected Precision RTD Sensor

- Explosion-Proof Construction

- Calibration Chart Provided

- Input Power 115/230 VAC or 24 VDC

Common Applications

- Protecting Critical Process Equipment

- Leak Detection

- Flow / No Flow of Liquids or Gas

- Pressure Relief Valve Monitoring

- Water Treatment Systems

- Water Cooled Equipment

Advantages of Thermal Instrument Mass Flow Swithces

- No Moving Parts

- Wide Turndown

- Repeatable

- Sensors Protected from Passing Fluid

- Built for Industrial Applications

- Multiple Process Connections

- Exotic Materials & Sanitary Surface Finishes Available

INSERTION PROBE THERMAL MASS (Model: 9500P)

Thermal Instrument Model # 62-9 is a versatile flow measurement solution for both liquid and gas flows in larger pipe sizes, ventilation ducts, and stacks. The insertion probe style is adaptable to various line sizes and offers a variety of process connections see more…

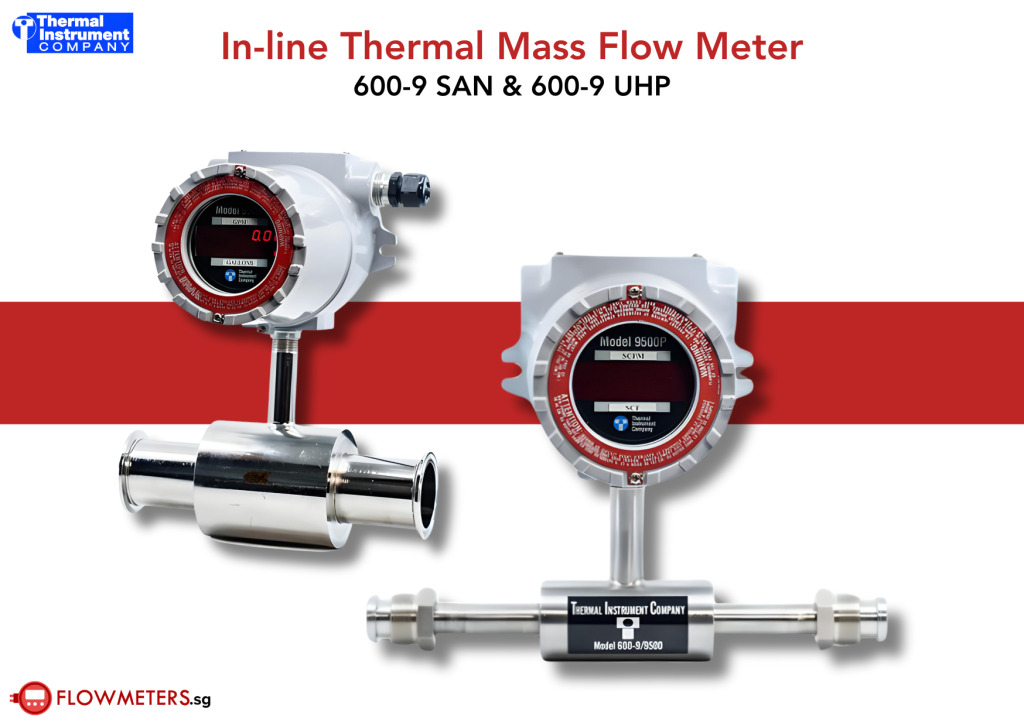

IN-LINE THERMAL MASS (Model: 600-9)

These Thermal Instrument inline models are constructed of 316L, low sulfur stainless steel down to 10-15 RA finish and offer “CIP/SIP” clean-in-place design. These models provide sanitary measurement options for our clients in the Food & Beverage, Pharmaceutical, and Semi-conductor industries see more…

IN-LINE THERMAL MASS (Model: 600-9 SAN)

We introduced our unobstructed in-line model for sanitary, clean, and ultra-high pure applications in the 1980’s. Since then, they have been utilized in pharmaceutical, semiconductor, and numerous food and beverage applications to name a few see more…