Measuring flow in small pipes and tubes can be solved by a wide range of mostly mechanical type devices where it is not inconvenient, neither impractical and economical. Some of the common ways to measure small pipe flow is to use Gear Flow Meters and even Coriolis Meters where the accuracy and repeatability justifies the price.

Introducing the SGF605 Ultrasonic Flow Meter

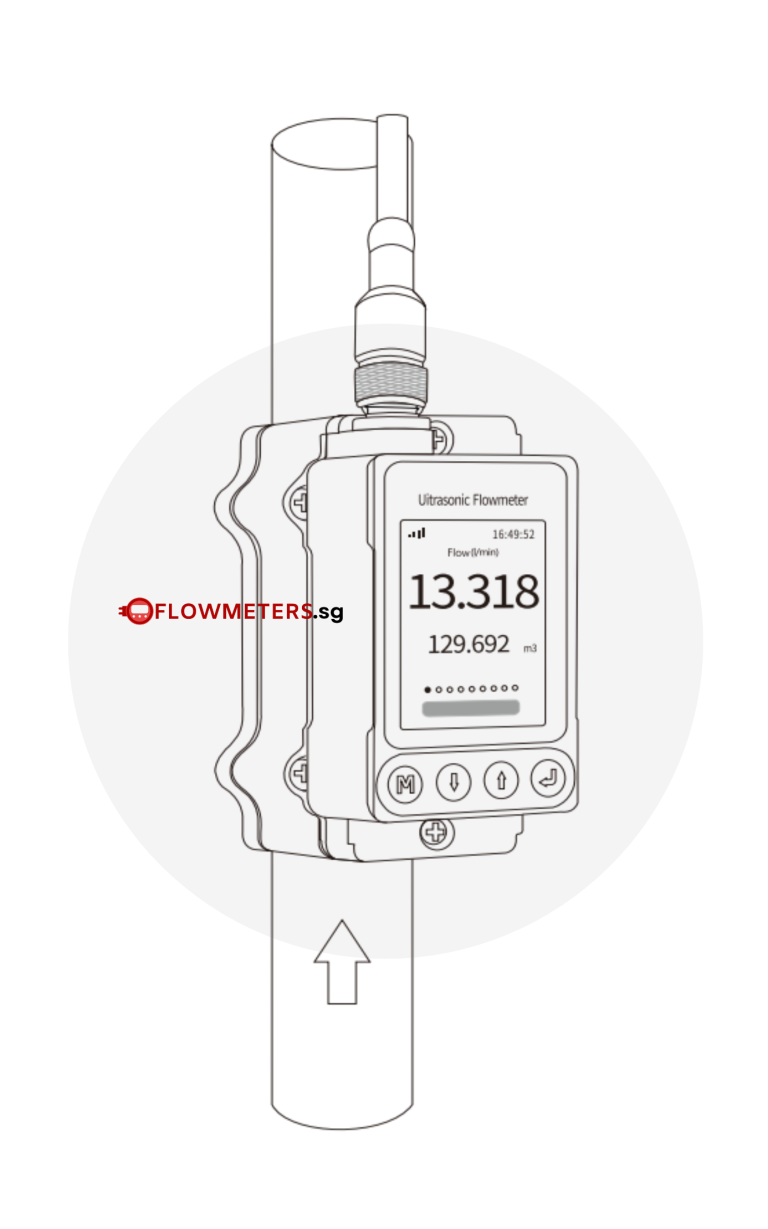

With our many decades of experience with clamp-on flow meters we have discovered a niche market for certain of our customers who are familiar with large clamp-on ultrasonic flowmeters and are eager to find alternative solutions using the same technology but on applications where pipes and tubes are small ranging from DN6 and above.

The options (as mentioned previously) could be the installation of a micro-flow meter using mechanical method e.g. Turbine Meter, Oval gear, Circular Gear and even Coriolis but where the SGF605 meets the customer’s expectations in regards to accuracy and repeatability; it now becomes a viable option to those of us who for some reason find it either impractical, unsafe or even not commercially viable to use a traditional technology.

NO CUTTING OF PIPES OR TUBES NEEDED

NO PROCESS INTERRUPTION

EASY INSTALLATION IN MINUTES

Clamp-on Meter

SGF605 Specifications

- Accuracy: ±2.0% (±0.3m/s ~ 5.0m/s)

- Flow range: 0.1m/s ~ 5.0m/s

- Repeatability: 0.8%

- Analog output: 4-20mA; maximum load: 600Ω

- Power supply: 24VDC, 3W

- Liquid temperature: -10℃-50℃

- IP grade: IP65

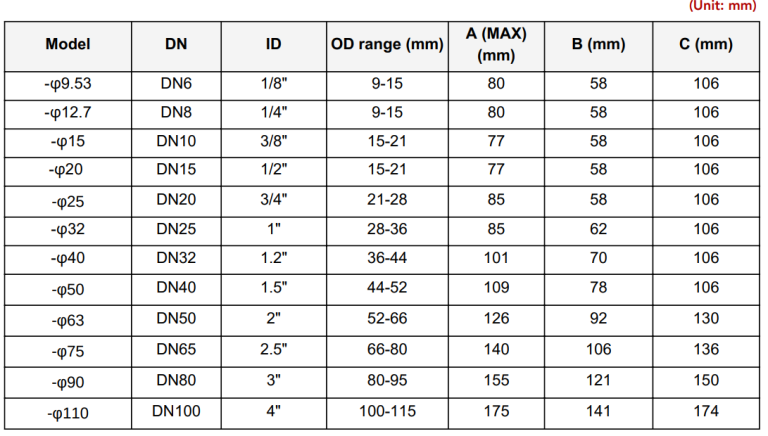

- Pipe range: DN6~DN100 (OD9~OD115)

- Communication: RS485, support Modbus communication protocol

- Keypad: Four light touch buttons

- Screen: 2.4″ 320*240 IPS LCD can 360 spins and easy to read.

- Totalizer: Seven-bit digit

- Viscosity: <300CST (mm²/s)

- Environment humidity: 0-95% relative humidity, without condensation