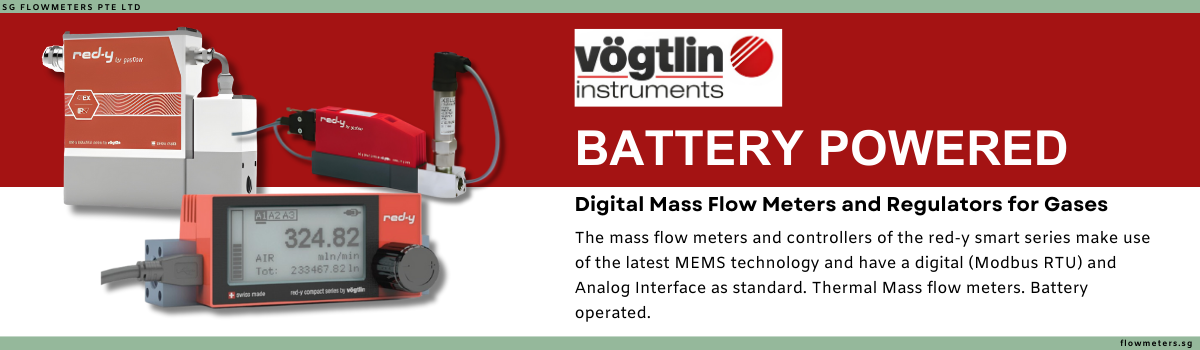

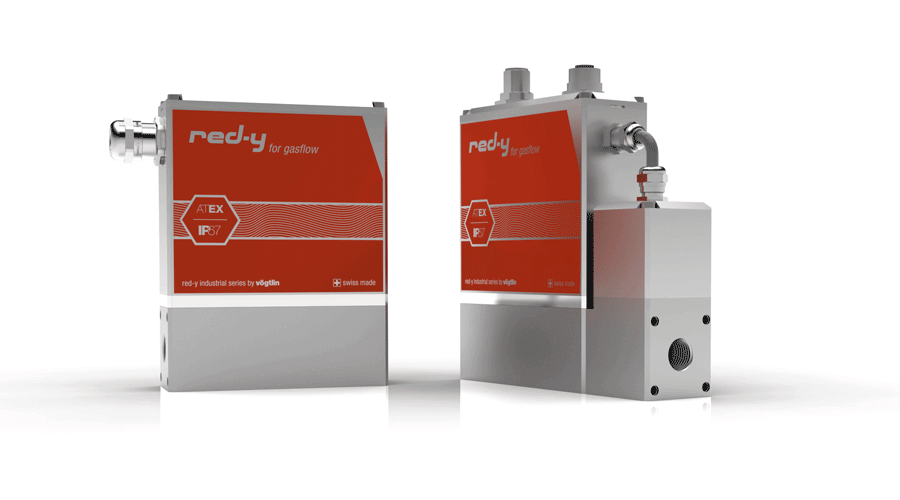

Red-y Industrial Series

Mass Flow Meters & Controllers with IP67 & Ex Protection

Reliable technology and industry standard interfaces for rough environments: Our tried and tested thermal mass flow meters and controllers for gases now available as IP67 / NEMA 6 version.

Accurate Measurement

The mass flow devices offer high accuracy and a wide dynamic range with the 2 different instrument versions “Standard” and “Hi-Performance”:

Accuracy up to ± 0.3% of full scale + ±0.5% of reading

Turndown ratio 1 : 100 (extended turndown ratio on request)

Analog & Digital

The red-y industrial mass flow meters and controllers make use of the latest MEMS technology and have a digital (Modbus RTU) and analog interface as standard.

IP67 / NEMA 6 Protection

The instruments offer IP67 / NEMA 6 protection against solid particles and water.

ATEX Certification

red-y industrial devices come along with ATEX certification (Category 3 / Zone 2 & 22)

Multiple Connections

The red-y industrial series is available with different connection types: Cable gland with compression fitting or optional M12 plug on top

Setup Tool get red-y

Efficient device setup with the free get red-y software:

- Service tool for remote maintenance.

- Switch gas type.

- Switch measurement units.

- Adjust control parameters.

Options

Multigas (option)

One meter or controller can be used for up to 10 different gases or gas mixtures.

Profibus

The instruments are available with Profibus interface: DP-V0 & DP-V1 protocols.

3-Year Warranty

High-quality components ensure long and trouble-free operation (does not apply to calibration, options and accessories).

Types & Options Red-y Industrial Series

Red-y Industrial Meter GIM

Flow up to 450 ln/min (480 SLPM)

Body size ¼” and ½”

Stainless steel 316L version

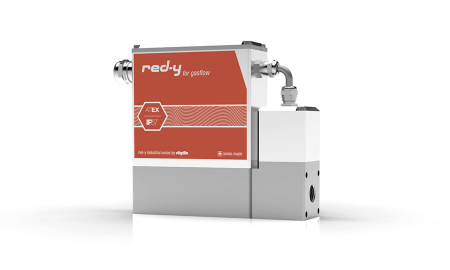

Red-y Industrial Controller GIC

Flow up to 450 ln/min (480 SLPM)

Body size ¼” and ½”

Stainless steel 316L version

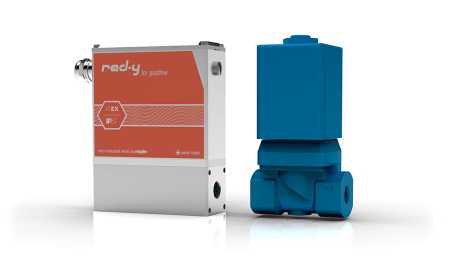

Red-y Industrial Controller GIE

Flow up to 450 ln/min (480 SLPM)

Body size ¼” and ½”

Stainless steel 316L version

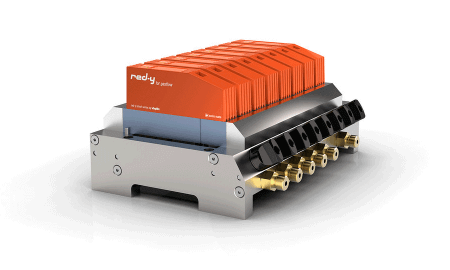

Customized OEM Solutions:

For a wide range of applications, the thermal mass flow meters and mass flow controllers offer you a significant optimization and simplification of your processes.

Technical Specifications

MEASURING RANGES

Body size ½” from 0 … 60 ln/min to 0 … 450 ln/min (from 0 … 65 SLPM to 0 … 480 SLPM)

INSTRUMENT VERSIONS

The economic solution

Turndown ratio: 1: 50

With highest accuracy and turndown ratio

(available for GIM < 200 ln/min (200 SLPM) /

GIC < 150 ln/min (150 SLPM) (air))

Turndown ratio: 1: 100

*An additional error of ±0.25% may apply for analogue signals

PERFORMANCE DATA

*O2 & N2 are calibrated with air

Meter: 50 ms; Controller: 150 ms

Meter: max. 100 mA; Controller: max. 250 mA (except GIE)

< 1 sec. for full accuracy

MATERIALS

Stainless steel 316L (see operating instructions for wetted parts)

EPDM (FDA), optional FKM

INTEGRATION & INSTALLATION

G½” (BSPP* female) up to 450 ln/min (480 SLPM)

*British Standard Pipe Parallel

(both connection IP67 protected)

Please contact the manufacturer for further information.

SAFETY

16 bara (240 psia)

< 1 x 10-6 mbar l/s He

II 3D Ex tc IIIC T100°C Dc (Category 3 / Zone 22)